On this page

Table of Contents

If you’re still building your foundation in basic electricity, start with this beginner-friendly overview: 🔹 “Electricity 101: The Complete Beginner’s Guide to How Power Really Works”

After reading it, the concepts in this article will make a lot more sense.

What Is a VFD (Variable Frequency Drive)? A Beginner-Friendly Guide With Real-World Examples

If you’ve ever typed “what is a VFD” into a search bar or heard the term on a jobsite and just nodded along, this guide is for you. We’ll keep it practical and focus on real motors, pumps, and fans you actually see in buildings.

If you also want a more formal, textbook-style definition, the Variable-frequency drive article on Wikipedia gives a good high-level overview of how VFDs are defined in industry and standards.

You’ve probably heard people say things like:

“Go for the variable-speed model — it’s way more energy-efficient.”

Behind a lot of that “variable-speed” magic is one device:

the VFD — Variable Frequency Drive.

If you work with HVAC systems, booster pumps, conveyors, fans, or you’re just trying to understand your building’s mechanical room, learning what a VFD is will help a lot of things suddenly make sense.

In this article, we’ll walk through:

Why VFDs exist in the first place

How they work internally (AC → DC → AC)

How a VFD actually controls motor speed

Typical applications in homes, commercial buildings, and plants

Chapter 1 – Why Do We Even Need VFDs?

Let’s start with a one-sentence version:

Traditional motors run at full speed as soon as you turn them on. A VFD lets the motor run only as fast as the job actually needs.

A standard induction motor connected straight to utility power in the U.S. (60 Hz) spins at basically one fixed speed. When you hit “start,” it jumps there almost immediately.

Think about:

- A booster pump in a mid-rise apartment building

- A cooling tower fan on a commercial rooftop

- A supply fan in an office air-handling unit

Even if the building only needs a little bit of flow, the motor still goes close to full speed. That simple setup is cheap, but it creates three big problems:

- High energy use

The motor is always running at “full speed,” even when the system only needs half the flow. Over time that’s a lot of extra kWh on the utility bill. - High mechanical stress

Across-the-line starts mean big inrush currents and sudden torque. Pumps, belts, bearings, and piping feel that “yank” every time you start the motor, which shortens equipment life. - Poor control

With a fixed-speed motor, your only options are basically ON, OFF, or maybe a few steps with throttling valves or dampers. It’s hard to match changing demand during the day.

A VFD exists to fix all three.

By controlling the frequency and voltage going to the motor, a VFD lets you:

- Ramp the motor up smoothly

- Run at partial speed when demand is low

- Reduce mechanical shock and noise

- Cut energy use in variable-torque loads like fans and pumps

So if someone on your team asks, “What is a VFD?”, you can answer like this:

A VFD is an electronic drive that takes fixed-frequency AC power and turns it into adjustable-frequency AC power so your motor can run at the speed the system actually needs.

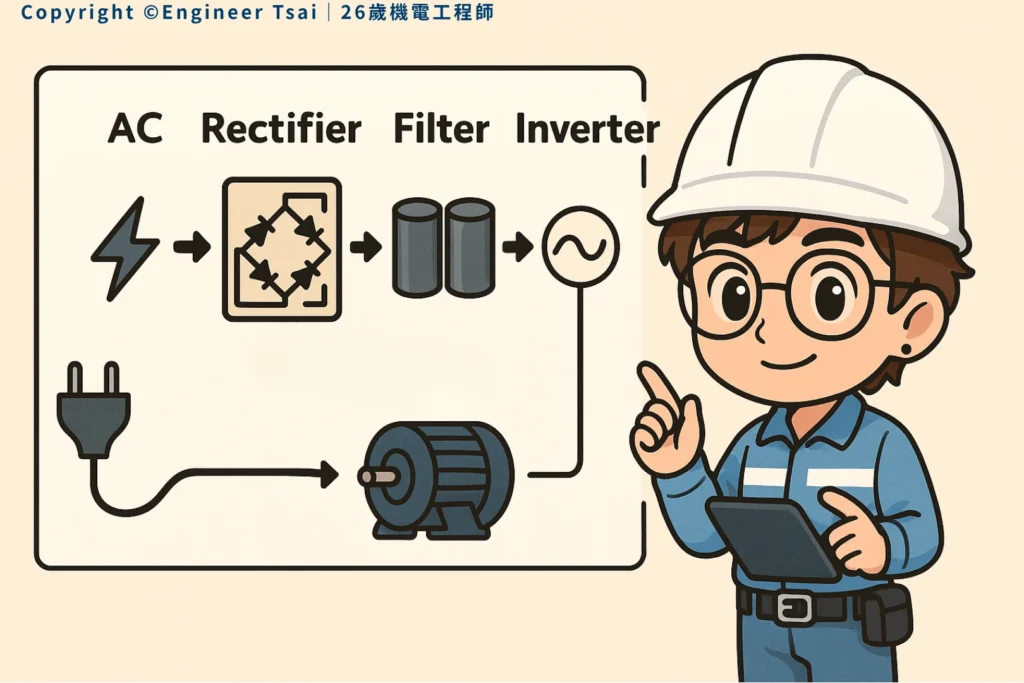

Chapter 2 – How a VFD Works: AC → DC → Adjustable-Frequency AC

On a one-line diagram, a VFD just looks like a box between the breaker and the motor. Inside that “box,” though, the power does something like this:

Utility AC → Rectifier → DC bus → Inverter → Adjustable AC to the motor

In plain language, a VFD is doing three main things.

1. Rectification: AC to DC

The VFD first receives three-phase (or sometimes single-phase) AC from the panel.

Inside the front end, a rectifier — often a diode bridge — converts that AC into DC.

You can think of it as:

- Taking the positive and negative swings of AC

- Flipping them so current flows in one direction

- Creating a pulsating DC voltage

This isn’t clean, flat DC yet, but it’s the first step.

2. Filtering and Smoothing: Cleaning Up the DC Bus

Next, the VFD uses capacitors and sometimes additional filters to smooth out that pulsating DC.

This creates a more stable DC bus voltage:

- Fewer ripples

- More consistent voltage level

- A solid “energy reservoir” the inverter can pull from

This DC bus quality directly affects the quality of the AC waveform the VFD sends to the motor.

3. Inversion: DC Back to Adjustable-Frequency AC

Finally, the VFD’s inverter section uses power electronic switches (often IGBTs — Insulated Gate Bipolar Transistors) to chop that DC up and reassemble it into a new AC waveform.

The key point:

Now the VFD can control both the frequency and the voltage of that AC.

That means it can:

- Output 30 Hz instead of 60 Hz for half-speed

- Adjust voltage to keep the V/Hz ratio right for the motor

- Ramp speed up and down instead of going “zero or full”

So in short:

A VFD isn’t “creating” extra power. It’s re-timing and reshaping the power so the motor runs in a way that matches the load.

Chapter 3 – How a VFD Actually Controls Motor Speed

For a standard three-phase induction motor, the synchronous speed is given by:

n = (120 × f) / p

Where:

- n = synchronous speed (RPM)

- f = frequency (Hz)

- p = number of poles

So if you cut the frequency from 60 Hz to 30 Hz with a VFD, the theoretical synchronous speed is cut in half.

The VFD uses this relationship to control speed:

- Increase frequency → motor speed goes up

- Decrease frequency → motor speed goes down

Of course, in the real world you also look at torque and cooling, but conceptually this is the core.

Why Small Speed Changes Matter So Much: Fan and Pump Loads

For fans and pumps, a small change in speed can make a huge difference in power.

A simple rule of thumb:

For many fan and pump loads:

- Flow ≈ speed

- Pressure ≈ speed²

- Power ≈ speed³

So if you reduce speed from 100% to 90%:

- Speed = 0.9

- Power ≈ 0.9³ ≈ 0.73

That means power can drop to around 73% of the original, just by slowing down the motor a little.

This is why so many building upgrades look like this:

- Old setup:

- Constant-speed pump + throttling valve

- New setup:

- VFD-controlled pump + pressure sensor

You stop forcing the pump to run full speed and then “choking” the flow with a valve. Instead, you let the pump itself slow down when demand is low — and the energy savings show up on your utility bill.

Chapter 4 – Common VFD Applications (With U.S.-Style Examples)

VFDs show up in more places than most people realize. Here are some of the most common examples you’ll see in homes and buildings in the U.S.:

- 🏭 Industrial equipment

Conveyors, process fans, blowers, and pumps that need to match production rates instead of just running flat-out all day. - 🌬 HVAC systems

Supply and return air fans, cooling tower fans, and chilled water pumps. VFDs help keep temperature and pressure stable without constant cycling. - 🛗 Elevators and escalators

Smooth acceleration and deceleration, less jerk for passengers, reduced gear and brake stress. - 🧺 Modern residential appliances

“Inverter” air conditioners, variable-speed compressors in refrigerators, and high-efficiency washing machines use VFD-style control inside. - 🚰 Booster pumps and domestic water systems

In mid-rise and high-rise buildings, VFD-controlled booster pumps can maintain steady pressure while cutting down on noise and pressure spikes.

A simple rule of thumb:

If there’s a motor + changing load + pressure to reduce energy costs, a VFD is worth at least considering.

Chapter 5 – Practical Design and Selection Tips

VFDs are powerful tools, but they’re not magic boxes you can just bolt in anywhere. When you design or retrofit a system, keep these points in mind.

1. Is the Motor Suitable for VFD Use?

Not every motor loves being run at low speed for long periods. Watch out for:

- Very old or specialty motors

- Motors whose cooling fans are mounted on the shaft (they cool less at low speed)

- Applications that expect full torque at very low RPM

For critical equipment, it’s worth checking:

- Motor nameplate and manufacturer recommendations

- Insulation class and VFD-rated compatibility

2. Get the Basic Parameters Right

A mis-configured VFD can make a good motor behave badly. At minimum, make sure settings like these are correct:

- Rated motor voltage and current

- Rated frequency (typically 60 Hz in the U.S.)

- Minimum and maximum frequency limits

- V/Hz curve or control mode (V/Hz, sensorless vector, etc.)

Bad settings can show up as:

- Overheating

- Low torque

- Nuisance trips

- Poor speed regulation

3. Pair the VFD With Proper Protection

Even with all the smart electronics inside, you still need proper protection around the drive:

- Circuit breaker or fused disconnect

- Overload protection (sometimes built into the drive, sometimes external)

- Under-voltage / over-voltage protections

- Surge protection, especially in areas with lightning or poor power quality

Make sure your protection scheme actually matches the VFD + motor combination, not just what was there before.

4. Think About EMI and Harmonics

Because VFDs use high-frequency switching, they can:

- Create electrical noise that bothers nearby sensitive equipment

- Introduce harmonics into the power system

- Cause nuisance tripping of some types of ground-fault or residual-current devices

To reduce issues:

- Follow the manufacturer’s grounding and bonding recommendations

- Use shielded cable where required

- Consider line reactors, harmonic filters, or special breakers if needed

For larger drives, coordination with your electrical engineer and utility is a good idea.

5. Don’t Ignore Heat and Space

VFDs generate heat. If you tuck them into a cramped panel in a hot mechanical room with no airflow, you’re asking for derating and premature failures.

When you design or retrofit:

- Check the ambient temperature rating

- Allow enough spacing around the drive for ventilation

- Consider dedicated cooling or better enclosure placement for larger systems

FAQ

Q1: What is a VFD in simple terms?

A VFD (Variable Frequency Drive) is an electronic device that takes fixed-frequency AC power, converts it to DC, and then creates a new AC output with adjustable frequency and voltage. In simple terms, it’s a speed controller for AC motors that lets them run only as fast as the job requires.

Q2: How is a VFD different from a regular motor starter?

Traditional starters (across-the-line, magnetic contactors, star-delta) mainly control when the motor turns on and off. Once the motor is running, it’s basically locked to 60 Hz and full speed.

A VFD continuously controls the frequency and voltage, so the motor can:

Ramp up smoothly

Run at partial speed when demand is low

Reduce mechanical stress and inrush current

Q3: Do VFDs really save energy? When is it most noticeable?

Yes — especially on fans and pumps where torque roughly follows the square of speed and power follows the cube of speed. For many of these loads, dropping speed from 100% to 90% can cut power to about 73%.

You’ll see the biggest impact in:

HVAC supply and return fans

Cooling tower fans

Chilled and condenser water pumps

Domestic water booster pumps in buildings

Anywhere flow and pressure needs change over the day, a VFD has strong potential to save energy.

Q4: What should I think about before adding a VFD to a system?

At a minimum:

Motor suitability – Is the motor designed or approved for VFD use and low-speed operation?

Heat and space – Is there enough ventilation and panel space for the drive?

Power quality and wiring – Do you need filters, reactors, or shielded cable to manage EMI and harmonics?

Protection and coordination – Are your breakers, overloads, and grounding set up correctly for a VFD-driven system?

For critical equipment, it’s smart to involve an experienced electrical or mechanical engineer.

Q5: What knowledge do I need before learning VFD setup and tuning?

It helps a lot if you already understand:

Basic electrical concepts – voltage, current, power, three-phase systems

Motor fundamentals – how induction motors work, the synchronous speed formula (n = 120f/p), nameplate data

Basic control hardware – contactors, overload relays, simple I/O, and safety interlocks

With that foundation, VFD wiring diagrams and parameter menus become much easier to understand.

Conclusion – The Quiet Hero Behind “Smart” Motors

By this point, you should be able to answer “what is a VFD” in your own words and point to a few real-world examples in your home, your office, or your building’s mechanical room.

A VFD will never be the star of a marketing brochure. You don’t see it from the lobby. Tenants and office workers don’t talk about it.

But behind stable temperatures, quiet pumps, and lower utility bills, there’s often at least one variable frequency drive doing its job in a panel somewhere.

Understanding what a VFD is and how it works gives you:

- Better conversations with contractors and vendors

- Smarter decisions when you design or retrofit systems

- A clearer path if you’re moving from office work into the electrical or HVAC trades

If you’re an apprentice, a career-switcher, or a curious homeowner, you don’t have to learn everything at once. Start with:

- The relationship between frequency, voltage, and motor speed

- The basic AC → DC → AC path inside a VFD

- A few real-world applications you see around you every day

From there, manuals and wiring diagrams will start to look a lot less scary.

If you’ve seen interesting VFD projects in your building, or you’re wondering whether a specific fan or pump would benefit from a drive, feel free to share your situation in the comments — real-world cases are where this knowledge really clicks.

📌 Recommended next reads:

🔹 “What’s the Difference Between AC and DC Power?”

Get clear on the basics of AC vs. DC first. Once that makes sense, it’s much easier to picture how a VFD “hands off” between them in the middle.

🔹 “How Do Batteries Work? The Hidden Secret of Power Sources”

If you’re curious about the power side of the story, this article looks at electricity from the angle of “stored energy” and fills in another important piece of the puzzle.

Read next in this topic

- What Is Electricity ? Everything You Need to Know

- Current & Voltage for DIY Enthusiasts : Unlock the Basics

- AC vs DC: What’s the Difference and Why It Matters (From Phone Charging to 120 V Home Power)

- Basic Parts of an Electric Circuit (Power Source, Wires, Loads)

- Conductor vs Insulator: How Your Home’s Wiring Keeps You from Getting Shocked

- Ohm’s Law Explained: V = IR for 120V Home Circuits

- What Is a Resistor? How It Works, Types, and How to Choose the Right One

- Series vs Parallel Circuits: Simple Guide for Home Wiring (With Formulas & Examples)

- How Electromagnetic Wave and Electricity Shape Modern Technology

- What Is Voltage? Simple Definition, Everyday Examples, and Safety Tips

- What Is a Battery? How It Works, Types, and Everyday Uses Explained

- What Is Ampere’s Law? A Visual Guide to How Current Creates Magnetic Fields

- What Does a Capacitor Do? Uses, Energy Storage, and Everyday Examples

- Types of Electrical Wire: How to Choose the Right One for Your Home

- How AC Power Is Converted to DC: What’s Really Inside Your Phone Charger?

- Electrical Energy Conversion: How Energy Transforms for Everyday Use

- Magnetic Field and Current: The Core Relationship Behind Motors, Generators, and Wireless Charging

- How Do Magnets Work? From Fridge Magnets to Maglev Trains

- What Is Inductance? Inductor Basics for Real-World Circuits

- What Is Impedance? A Plain-Language Guide to Resistance, Inductive Reactance, and Capacitive Reactance